Neste Renewable Diesel Handbook

A summary of the Neste renewable diesel handbook as guide for shipowners

Neste Corporation calls its own HVO product “Neste Renewable Diesel” or “Neste MY Renewable Diesel™”. The common acronym “HVO” comes from the terms “Hydrotreated Vegetable Oil”. It meets the requirements of EN 15940 for paraffinic diesel fuels and is allowed as a blending component in EN 590 B7 diesel fuel without any fixed maximum percentage. In practice, the maximum amount of Neste Renewable Diesel to be blended is limited by the lower density limit in EN 590, which often limits the blending to ~30-50% of Neste Renewable Diesel. It is a high quality fuel that can be used to enhance the properties of the final diesel blend. No modifications to vehicles required and it has the same torque and maximum power as with fossil diesel fuel in modern engines. Furthermore, properties of HVO include:

No cold operability issues with severe winter grades.

Low tendency to form deposits in fuel injection system and fuel injectors.

No engine oil dilution issues or chemical incompatibilities with engine oil.

Possibility to design more fuel-efficient low-emission diesel engines (“diesel-FFV-vehicles”).

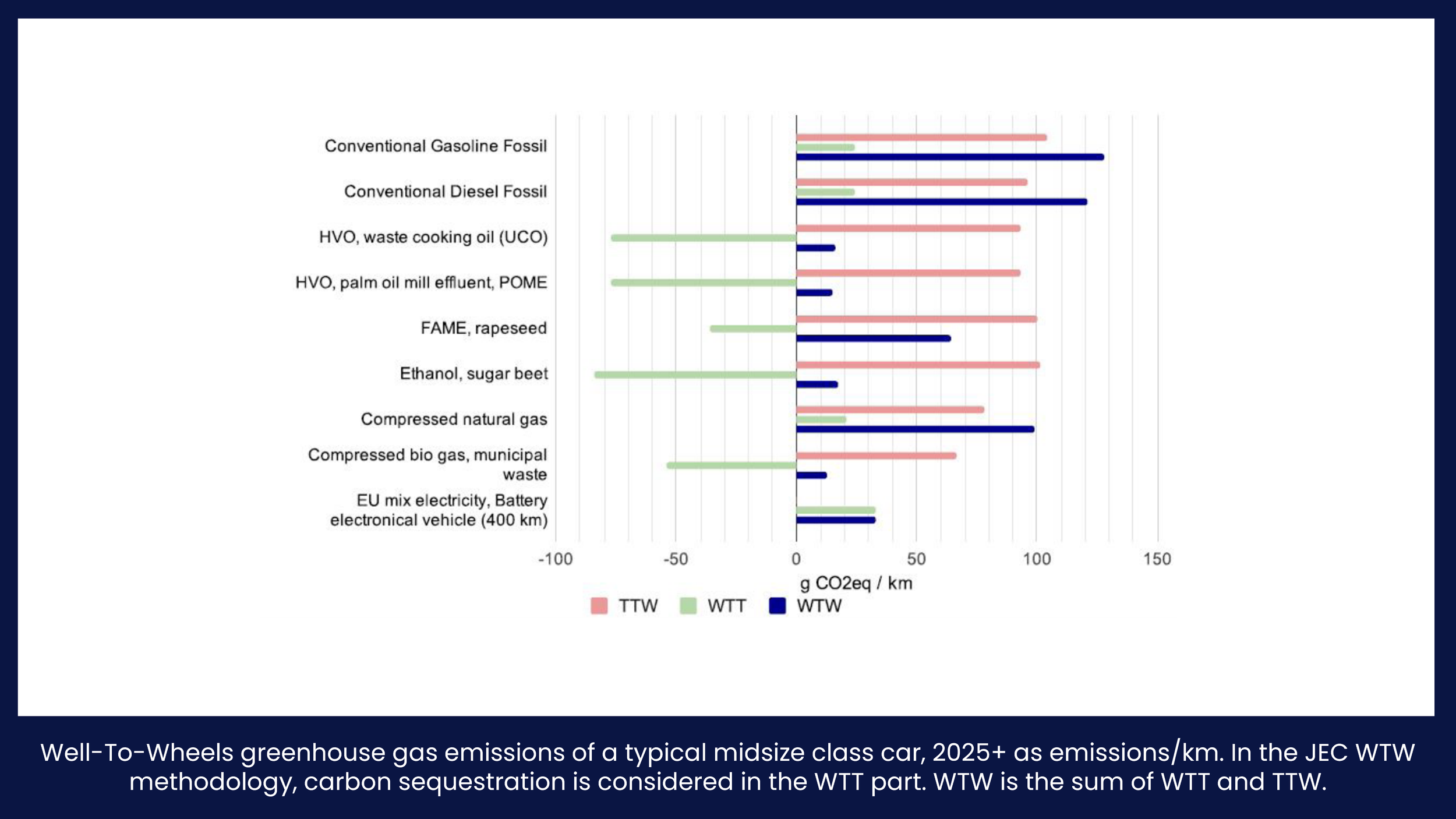

Reduces greenhouse gas emissions by 50−90%, pending on the stock and blend.

It should be noted that Sustainable Ships does not receive any revenue for promoting Neste - we simply believe it is one of the best biofuels available

General

The common acronym “HVO” comes from the terms “Hydrotreated Vegetable Oil” or “Hydrogenated Vegetable Oil”. They originate from the time before 2010 when only vegetable oils were used as feedstocks. Today HVO is increasingly produced from waste and residue fat fractions coming from the food industry, as well as from non-food grade vegetable oil fractions. Thus “HVO” and “Hydrotreated Vegetable Oil” are no longer accurate terms describing the origin of the fuel. However, those terms cannot be changed easily since they are common in the European regulation, fuel standards, and biofuel quality recommendations set by automotive companies. According to several chemistry experts, “Hydrotreated” referring to fuel processing is preferable over “Hydrogenated”, as the latter is commonly linked to the manufacturing of margarine. Neste Corporation calls its own HVO product “Neste Renewable Diesel” or “Neste MY Renewable Diesel™”.

“Renewable Paraffinic Diesel” has also been commonly used, as it is chemically a proper definition for product quality. However, this term also covers Biomass-to-Liquid (BTL) fuels made by Fischer-Tropsch synthesis and, therefore, does not define the feedstock and process used to produce “HVO”. Also the terms “HDRD”, i.e. “Hydrogenation Derived Renewable Diesel”, “Non Ester Renewable Diesel”, “Renewable Hydrocarbon Diesel”, and “HBD”, i.e. “Hydro-generated Biodiesel”, have been used especially in North America and the Far East. The European EN 15940 standard uses the term “Paraffinic Diesel Fuel from Hydrotreatment”. This handbook refers to isomerized, good cold operability and high cetane number (above 70) products meeting EN 15940 Class A requirements. In this document, “HVO”, “Neste Renewable Diesel”, “NRD” and “renewable diesel” are used to refer to such products.

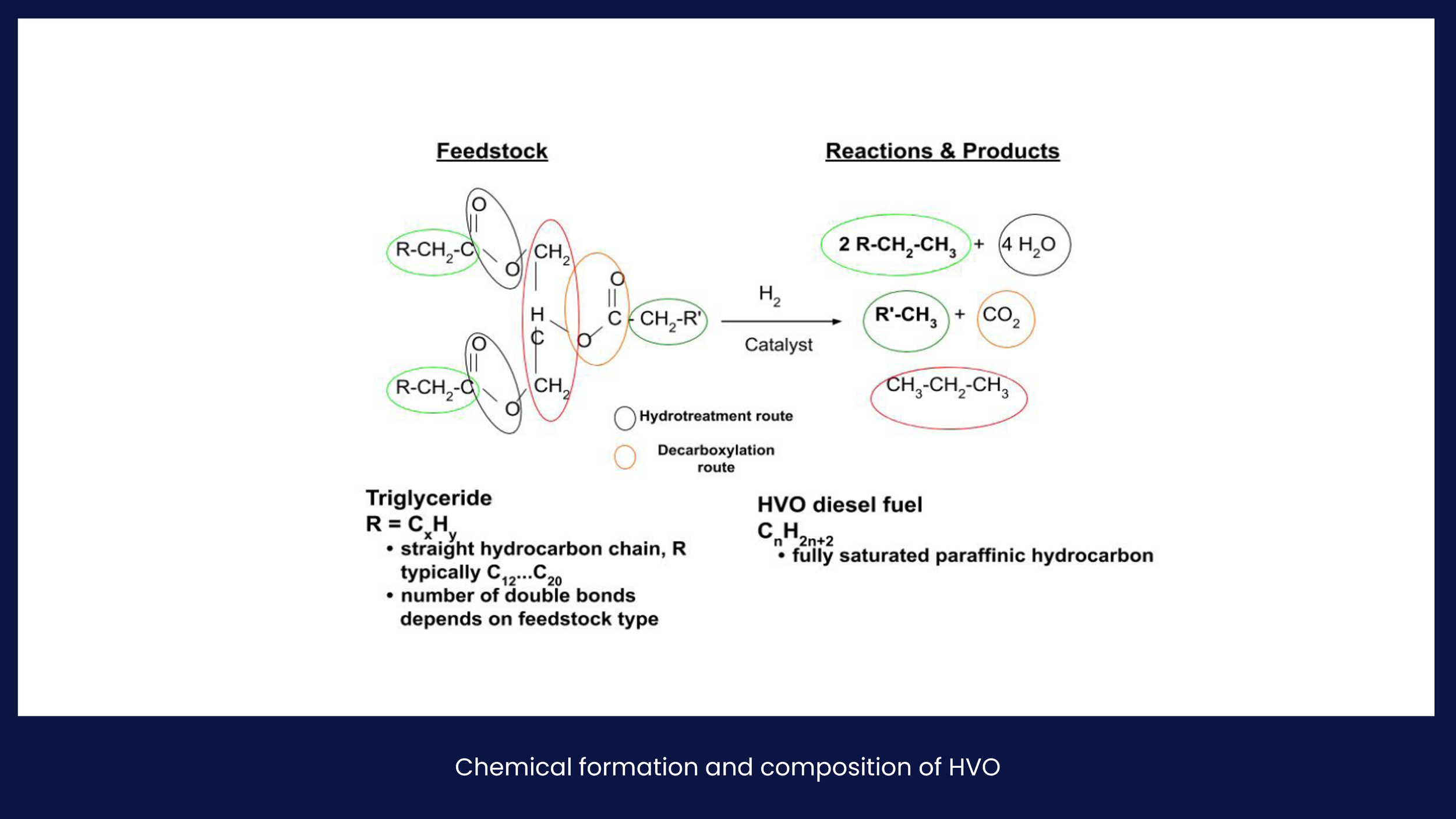

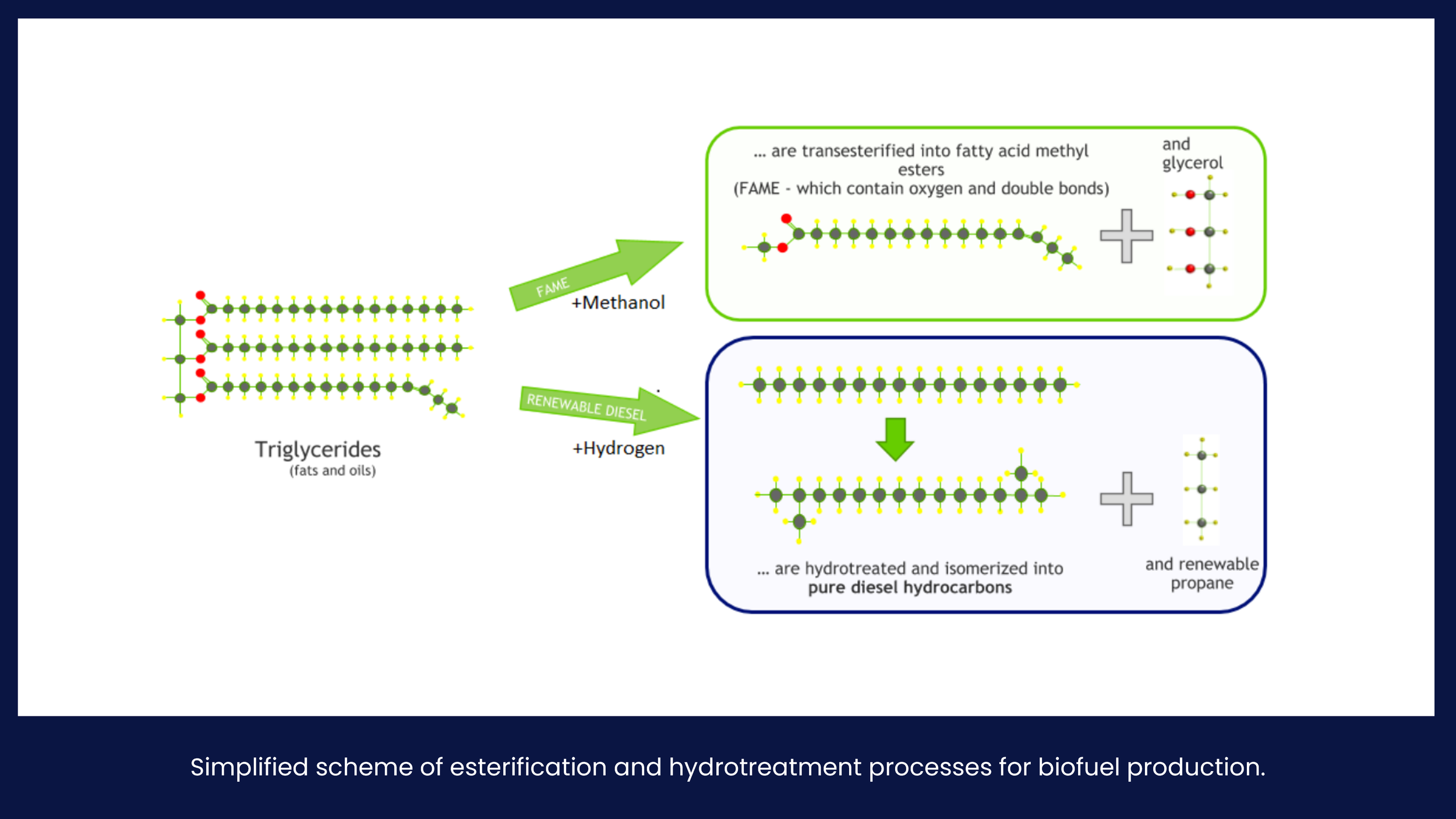

The hydrotreatment of vegetable oils as well as suitable waste and residue fat fractions through patented the NEXBTL™ process to produce HVO is an already mature commercial scale manufacturing process. It is based on oil refining know-how and is used for the production of biofuels for diesel engines. In the process, hydrogen is used to remove oxygen from, for example, triglyceride vegetable oil molecules and to split the triglyceride into three separate chains, thus creating hydrocarbons that are similar to existing diesel fuel components. This allows blending in any desired ratio without any concerns regarding fuel quality.

HVO is a mixture of straight chain and branched paraffins – the simplest type of hydrocarbon molecules from the clean and complete combustion point of view. Typical carbon numbers are C15...C18. Paraffins exist also in fossil diesel fuels, which additionally contain significant amounts of aromatics and naphthenes. Aromatics are not favourable for clean combustion. HVO is practically free of aromatics and its properties are quite similar to Gas-to-Liquid (GTL) and BTL diesel fuels made by Fischer Tropsch synthesis from natural gas and gasified biomass. At least the companies presented in Table 1 have developed stand-alone HVO production processes and products.

In many cases, the abbriation “XTL/HVO” is used for paraffinic fuels. XTL is a term used to describe synthetic GTL, CTL and BTL Fischer-Tropsch production paths. Since there are no practical methods for measuring paraffinic content, the paraffinic nature is proven by limiting aromatic content to practically zero. Nominally, fuel’s paraffinic purity is min. 98.5 wt-% “without any intentional adding of non-paraffinic material other than additives or markers” since 100.0% purity cannot be verified from a fuel sample because of inaccuracy of analytical methods.

Fuel Specifications

Meets the requirements of EN 15940 for paraffinic diesel fuels.

Allowed as a blending component in EN 590 B7 diesel fuel without any fixed maximum percentage.

Fulfils ASTM D975 requirements.

Ester type biodiesel (FAME) standard EN 14214 is not valid for Neste Renewable Diesel.

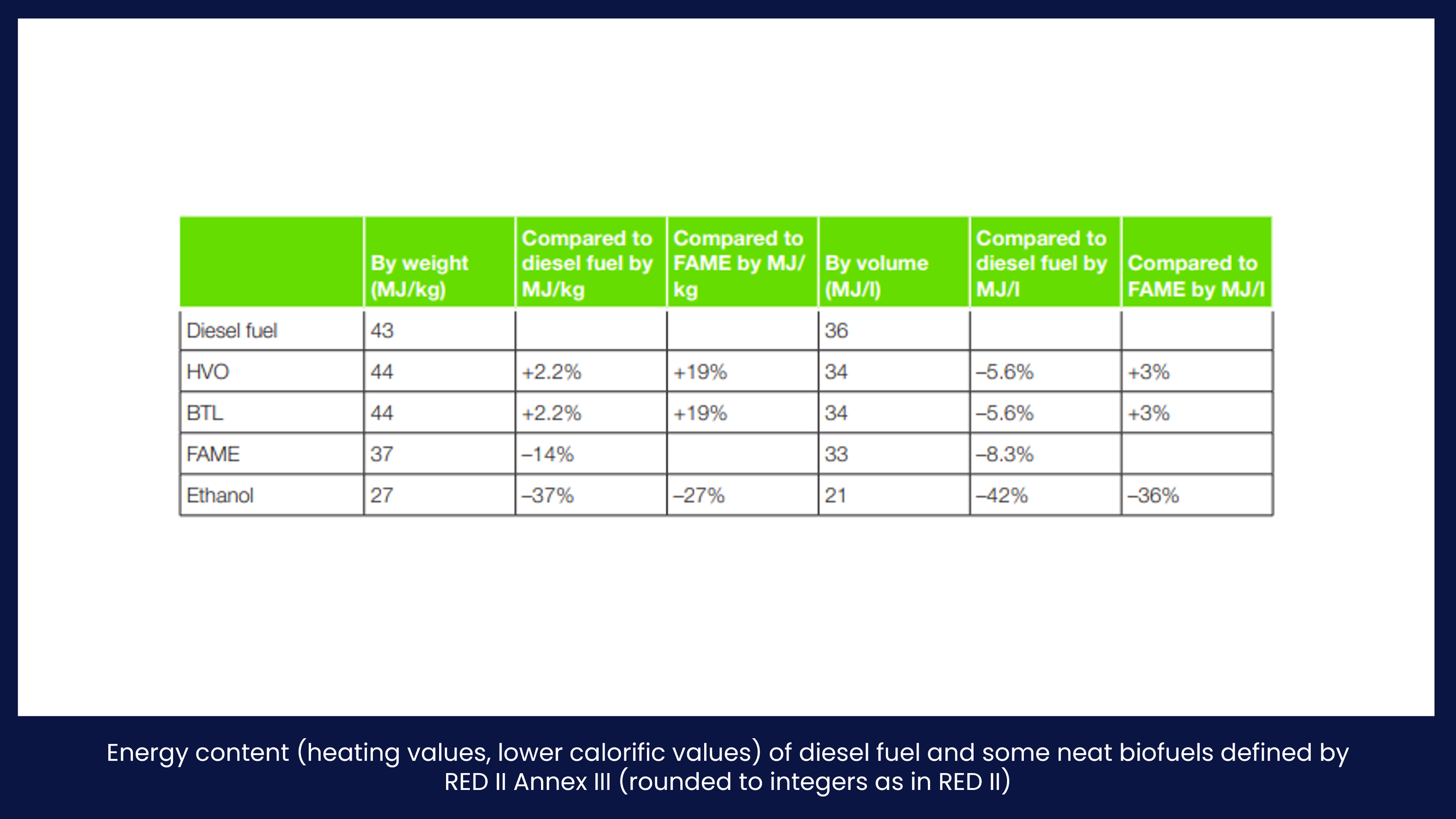

Energy content is defined in directive RED II 2018/2001/EU Annex II.

-

The EN 15940:2016 + A1:2018 + AC:2019 standard covers hydrotreated paraffinic renewable diesel fuel and synthetic Fischer-Tropsch products GTL, BTL and Coal-to-Liquid (CTL). In the future e-fuels might also be covered with this standard. Before publishing EN 15940, paraffinic diesel fuel was specified by CEN Technical Specification TS 15940:2012 and CEN Workshop Agreement CWA 15940:2009.

EN 15940 covers paraffinic diesel fuel used as such in vehicles, and it defines fuel properties at retail points. It does not take into consideration whether the fuel’s origin is fossil or renewable since that part of the fuel supply chain is regulated only in fuel and feedstock directives.

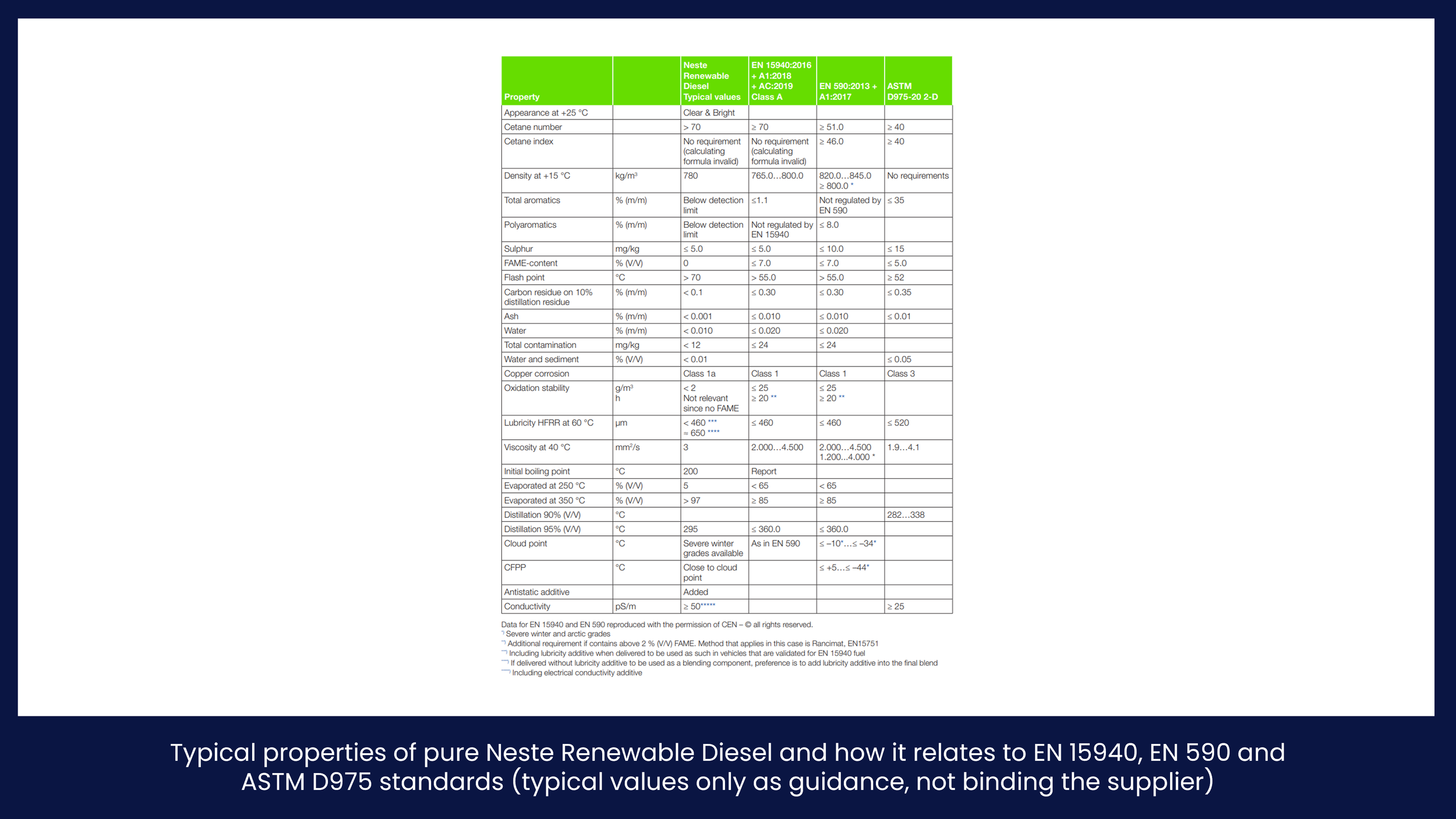

EN 15940 has two main fuel grades: High cetane class A (min. 70) and normal cetane class B (min. 51). Neste Renewable Diesel meets the EN 15940 class A. Neste Renewable Diesel as such also meets the European diesel fuel standard EN 590 in all respects, except density, which is below the lower limit. The American diesel fuel standard ASTM D975 and Canadian CGSB-3.517 are met as such, since they do not limit density of the fuel.

EN 15940 states “Paraffinic diesel fuel is not validated for all vehicles, consult vehicle manufacturer before use”. Even though paraffinic diesel should not cause any risks in engines or vehicles, Euro 6 and Euro VI exhaust regulations may formally require that vehicle manufacturers need to give an allowance to use paraffinic diesel.

Ester type biodiesel (FAME) standard EN 14214 is not valid for Neste Renewable Diesel, since Neste Renewable Diesel consists of hydrocarbons only. Originally, CWA 15940 did not allow FAME, but nowadays 7 vol-% FAME is allowed as a blending component in EN 15940 paraffinic diesel fuel.

The Fuel Quality Directive 98/70/EC with remarkable amendments by Directive 2009/30/EC lays down in Article 1(a) the fuel requirements that are related to health, environment and engine technology. Further, Article 1(b) determines targets for the reduction of greenhouse gas emissions for fuels, expressed in gCO2eq/MJ fuel’s calorific value at retail points.

Properties

One of the highest heating values among current biofuels.

Severe winter and arctic grades available, thanks to the isomerization process.

Usable either as 100% HVO fuel or as a “drop in” blending component within diesel fuel.

High quality component that can be used to enhance the properties of the final diesel blend.

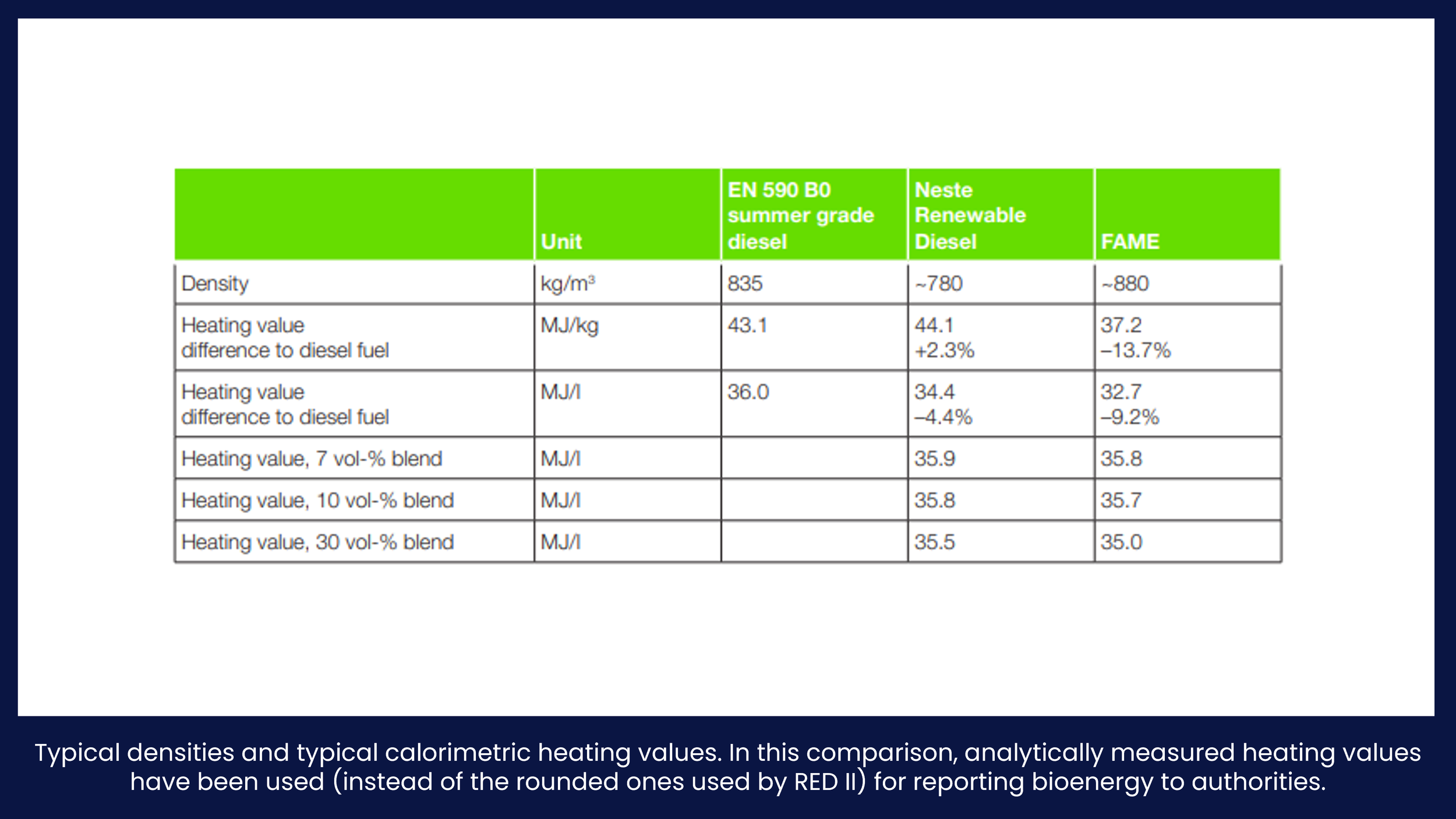

Lower density (780 kg/m3) compared to common European diesel fuels (800...845 kg/m3 ).

Higher energy content compared to FAME, both in MJ/kg and MJ/l.

Stability is good and comparable to fossil diesel.

Does not have similar storage stability challenges as FAME, and therefore NRD does not require a “best before” date.

Due to the low water dissolving property, the risk of microbial growth is similar to fossil diesel and no additional precautions are needed.

Requires a lubricity additive in the same way as sulphur free diesel fuels and GTL. Generally, similar types of lubricity additives can be used in fossil diesel fuel and Neste Renewable Diesel.

-

Neste Renewable Diesel (NRD) contains only n- and i-paraffins and can be used within XTL/HVO validated vehicles as is or blended as “drop in fuel” without a “blending wall” set by vehicle technology or limitations by fuel logistics. The properties of NRD have many more similarities with high quality sulphur free fossil diesel fuel than with FAME, which is a well-known biocomponent to oil companies. Moreover, the properties of Neste Renewable Diesel are very similar to the synthetic GTL diesel fuel, which has been considered to be the best diesel fuel regarding engines and tailpipe emissions. Thus, NRD offers the same compositional benefits as GTL but with remarkably lower greenhouse emissions. Neste Renewable Diesel can be evaluated with the same analytical methods as used with fossil fuels. Table 3 presents typical properties for NRD, and limits in the EN 15940, EN 590 and ASTM D975 standards.

When compared to standard diesel fuel with ~13.5 wt-% of hydrogen, Neste Renewable Diesel has higher heating value per mass due to the higher hydrogen content of ~15.2 wt-%.The energy content of NRD also is higher compared to FAME, both per litre and per kg; as a consequence, a slightly smaller blending ratio is needed to meet the same bioenergy mandate. When NRD and ethanol are compared, the volumetric benefit of Neste Renewable Diesel is significant since the heating value of HVO is 44 MJ/ kg, and for ethanol it is only 27 MJ/kg. This means that a remarkably lower amount of HVO in tons or cubic meters is needed to meet the same national biomandate compared to ethanol in case there is a combined biomandate for gasoline and diesel.

Performance

No modifications to vehicles required.

Same torque and maximum power as with fossil diesel fuel in modern engines.

No cold operability issues with severe winter grades.

Low tendency to form deposits in fuel injection system and fuel injectors.

No engine oil dilution issues or chemical incompatibilities with engine oil.

Possibility to design more fuel-efficient low-emission diesel engines (“diesel-FFV-vehicles”).

Supported in Worldwide Fuel Charter published by automotive and engine manufacturers.

-

Good ignition characteristics of diesel fuels improve cold start performance. The cetane number of the fuel defines its ignition quality. A number of modern engines can benefit from a higher cetane number when starting in very cold climates. The smoothness of operation, misfiring, smoke emissions, noise, and ease of starting are all dependent on the ignition quality of the fuel.

As discussed in detail in the Properties section, the cetane number of Neste Renewable Diesel is very high, above 70, because of its chemical composition, a mixture of n- and isoparaffins. Fuel economy is related to the heating value of the fuel. Although the heating value of Neste Renewable Diesel per volume is lower, the heating value per mass is higher due to the increased hydrogen content compared to standard diesel fuel.

Noteworthy is also that the energy content of NRD is higher compared to FAME, both per litre and per kg. Besides heating value, fuel viscosity is an essential parameter since it affects the atomization; the viscosity of Neste Renewable Diesel is well within the EN15940 and EN590 specification limits. To avoid excessive wear, fuel must have a minimum level of lubricity.

The use of fuels with poor lubricity can increase fuel pump and injector wear and, at the extreme, cause a total failure. Hydrotreated fuels have typically poor natural lubricity. However, this is easily resolved by treating the fuel with a lubricity additive. Malfunction can be caused by soluble gums or insoluble organic particulates formed by unstable diesel fuels. Both gums and particulates may contribute to injector deposits, and particulates can clog fuel filters.

The oxidation stability of NRD is on a very good level and, as a consequence, it has a low tendency to form deposits in the fuel injection system and fuel injectors.

In a nutshell, HVO offers improved performance in terms of operation, emissions, and durability, due to a higher cetane number than conventional diesel, a reasonable distillation range without high boiling fractions, a very high heating value, proper viscosity and good oxidation stability.

Blending

Allowed as a blending component in EN 590 B7 diesel fuel without any fixed maximum percentage. In practice, the maximum amount of Neste Renewable Diesel to be blended is limited by the lower density limit in EN 590, which often limits the blending to ~30-50% of Neste Renewable Diesel.

Preserves and even improves the properties of the final diesel fuel blend. Benefits depend on the blending ratio.

Minimum density specified in EN 590 limits the maximum amount of NRD that can be blended in the final fuel.

Can be blended in all ratios with ASTM D975 fuel, due to the absence of density limitations.

Some attention needed if FAME and renewable diesel are blended, especially regarding the precipitation of FAME originated impurities.

Blends well with GTL fuels.

-

Because Neste Renewable Diesel contains only n- and i-paraffins, it can be blended into diesel fuels as a “drop in fuel” without a “blending wall” set by vehicle technology or limitations by fuel logistics. Also the Fuel Quality Directive 2009/30/EC, recital 33, states that no limit is required for diesel-like hydrocarbon biofuels and hydrotreated vegetable oil. Regarding the actual blending procedure, the same considerations need to be taken into account as when two fossil diesels are blended together, such as temperature and density of the fuels. Compatibility with commonly used additives (lubricity, conductivity etc.), current logistics and practices, excellent storage stability and low tendency to pick up and dissolve water make Neste Renewable Diesel a convenient blending component.

In practice, the maximum amount of Neste Renewable Diesel to be blended is limited by the lower density limit in EN 590, which often limits the blending to ~30-50% of Neste Renewable Diesel. In blending recipes, the density behaves linearly; therefore, even more could be added if the density of the base diesel fuel is over 845 kg/m3 . This allows the usage of slightly heavier distillation fractions, which would otherwise be directed into lower profit products, such as heating gas oil. In the American ASTM D975, there is no limit for density – so there are no limits for adding Neste Renewable Diesel from that point of view.

Production

Neste Renewable Diesel is produced through the hydrotreatment route, a complex industrial process that needs high pressure and temperature.

Distillation range is within a similar range typical of European summer grade diesel fuel.

Lower final boiling point compared to FAME.

-

Traditional biodiesel is produced from vegetable oils by an esterification process. The products are called Fatty Acid Methyl Esters (FAME or “biodiesel”). Other acronyms are also used, such as Rape Seed Methyl Ester (RME), Soybean Methyl Ester (SME), Palm Oil Methyl Ester (PME), or Used Cooking Oils Methyl Ester (UCOME), depending on the used feedstock. Neste Renewable Diesel is produced through the hydrotreatment route, a complex industrial process that needs high pressure and temperature.

Neste spends 70% of all its R&D investments in pursuit of suitable new raw materials, especially waste and residues. With year-on-year increases, the supply of Neste Renewable Diesel from waste and residue material reached 80% in 2019; thus the use of such raw materials by Neste is very remarkable already today. The aim of the company’s current efforts is focused on the utilization of lower quality waste and residue materials, as well as on the development of promising new raw materials, such as algae and microbial oils.

Sustainability Criteria & Emissions

EU Renewable Energy Directive II - Gives default GHG values for some of the biofuel pathways to help fuel producers calculate the GHG emissions of the entire life cycle of fuel. Obligates Member States to have a minimum of 14% of the energy consumed in road and rail transport originated from renewable sources by 2030. Individual Member States may have even more challenging requirements.

The sulphur content is < 1 mg/kg, but, due to possible contaminants within normal diesel logistics, the specification is set to ≤ 5.0 mg/kg.

Can be used in blends to reduce the sulphur content of the final diesel fuel.

The ash content is < 0.001% and thus does not cause excess burden for modern exhaust aftertreatment systems.

Reduces engine out NOx , particulate (also nanosize), CO, HC, PAH, aldehyde and mutagenic emissions.

Reduces cold start smoke and emissions in winter conditions.

Effects seen already at 10...30% blending ratios.

Ash-free combustion offers a long lifetime for particulate filters.

-

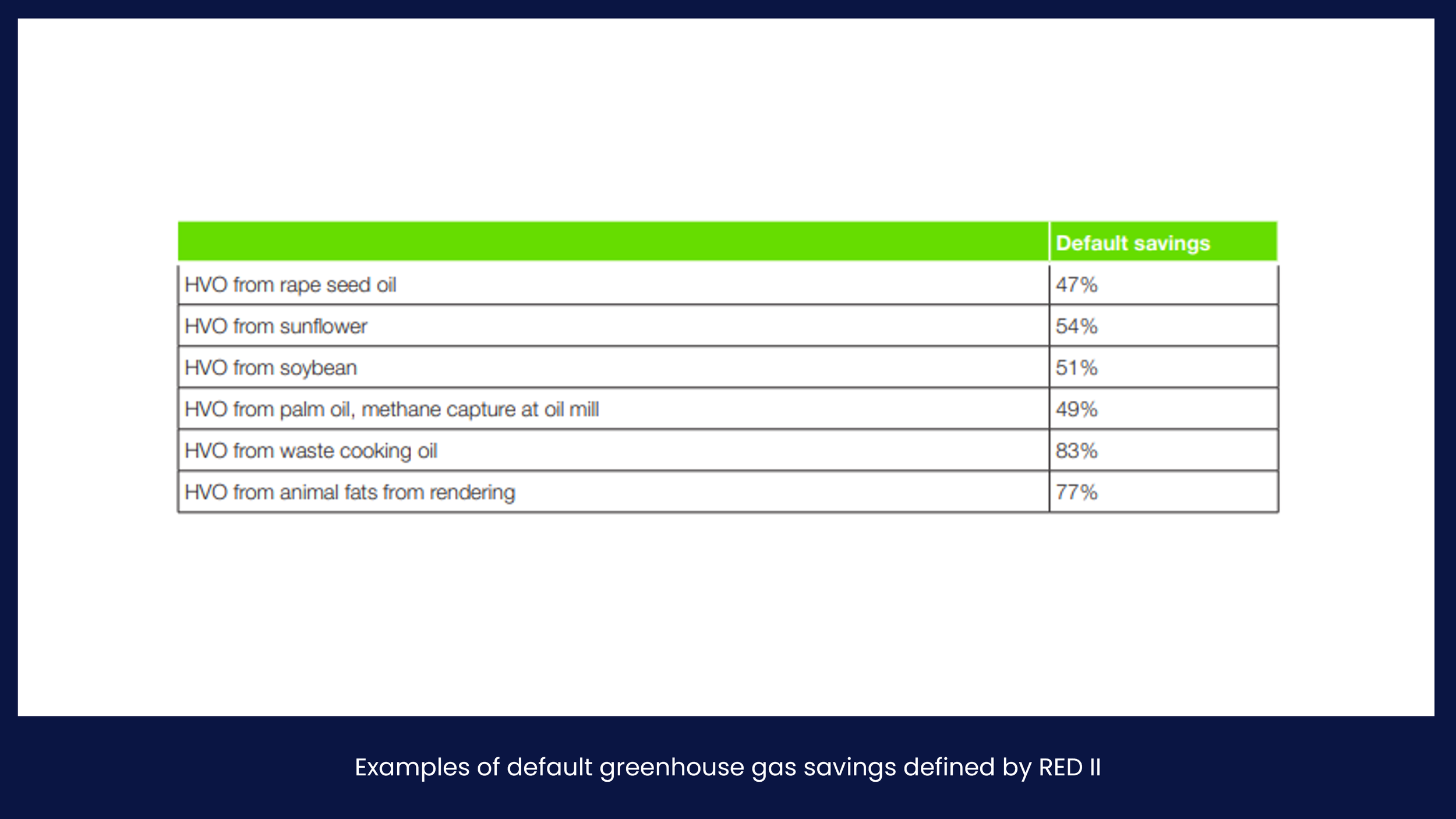

Neste Renewable Diesel reduces greenhouse gas emissions by 50−90%. The actual GHG savings from Neste Renewable Diesel, based on waste and residue raw materials, such as used cooking oil, is on average 90%.

The European directive promoting the use of renewable energy (“RED”, directive 2009/28/EC) requires that at least 10% of the energy used in the transport sector has to originate from renewable sources by 2020. In RED II (2018/2001/EU), each Member State is obligated to have a minimum of 14% of the energy consumed in road and rail transport as renewable energy by 2030. The Member States must update their legislation accordingly by the end of June 2021. In addition, the directive regulating fuel quality and environmental impacts (“FQD”, directive 2009/30/EC) demands a 6% reduction in fuel greenhouse gases (GHG) by 2020.

The requirement of 6% will continue after 2020. In addition, individual Member States may have even more challenging requirements. For example, Finland will increase the share of biofuels used in road transport to a minimum 30% by 2029, the major reason for which is the “Non-ETS sectors” (ETS, emissions trading system) greenhouse gas reduction regulation 2018/842/EU. The RED and FQD have common sustainability and GHG emission criteria that bioliquids used in transport must comply with. In RED II, some of these criteria are the same as in the original RED and FQD, but some are new or rewritten.

All sustainable renewable energy sources are taken into account in the fuel supplier obligation. Biofuel needs to be traced to its origin, for example, where the raw material has been cultivated. Waste and residue raw materials are traced to their collection point of origin. Additionally, there are bans that restrict biofuel raw material from areas like primary or highly biodiverse forests, wetlands, peatlands and nature protection areas.

There are caps restricting the use of some raw materials. The life cycle GHG emissions need to be assessed for all product steps: cultivation, raw material transport, all processing steps, fuel transport, distribution and final use of the fuel. It’s called the Well-To Wheels approach in the life cycle assessment (LCA).

The sum of all product chain steps is compared to the sum of the fossil fuel production steps and the result is the GHG savings. RED II has tightened the GHG saving limit criteria for biofuel production in new production sites:

• at least 50% on or before 5.10.2015

• at least 60% from 5.10.20.15-31.12.2020

• at least 65% after 1.1.2021

The RED, RED II and FQD give default GHG values for some of the biofuel pathways to help fuel producers with complicated GHG calculations. There are examples in Table 8. However, the directives give fuel producers the possibility to use partly default values or to calculate the biofuel pathway emissions with actual raw material, process and transport values on their own. Biofuel producers are required to have third party (e.g. ISCC certificate) verification of compliance with the sustainability and greenhouse gas emissions saving criteria annually.