ECA (Emission Control Area)

ECAs are sea areas that limit SOx and NOx emissions

0.10% [m/m] fuel for SOx and Tier III for NOx (pending vessel age)

Download Guide

The ECA guide is an E-Book that can help you separate sense from nonsense with ECAs, cost and compliance insights plus includes FAQs and references

More than 10,000 people worldwide watch this every year

Frequently Asked Questions

-

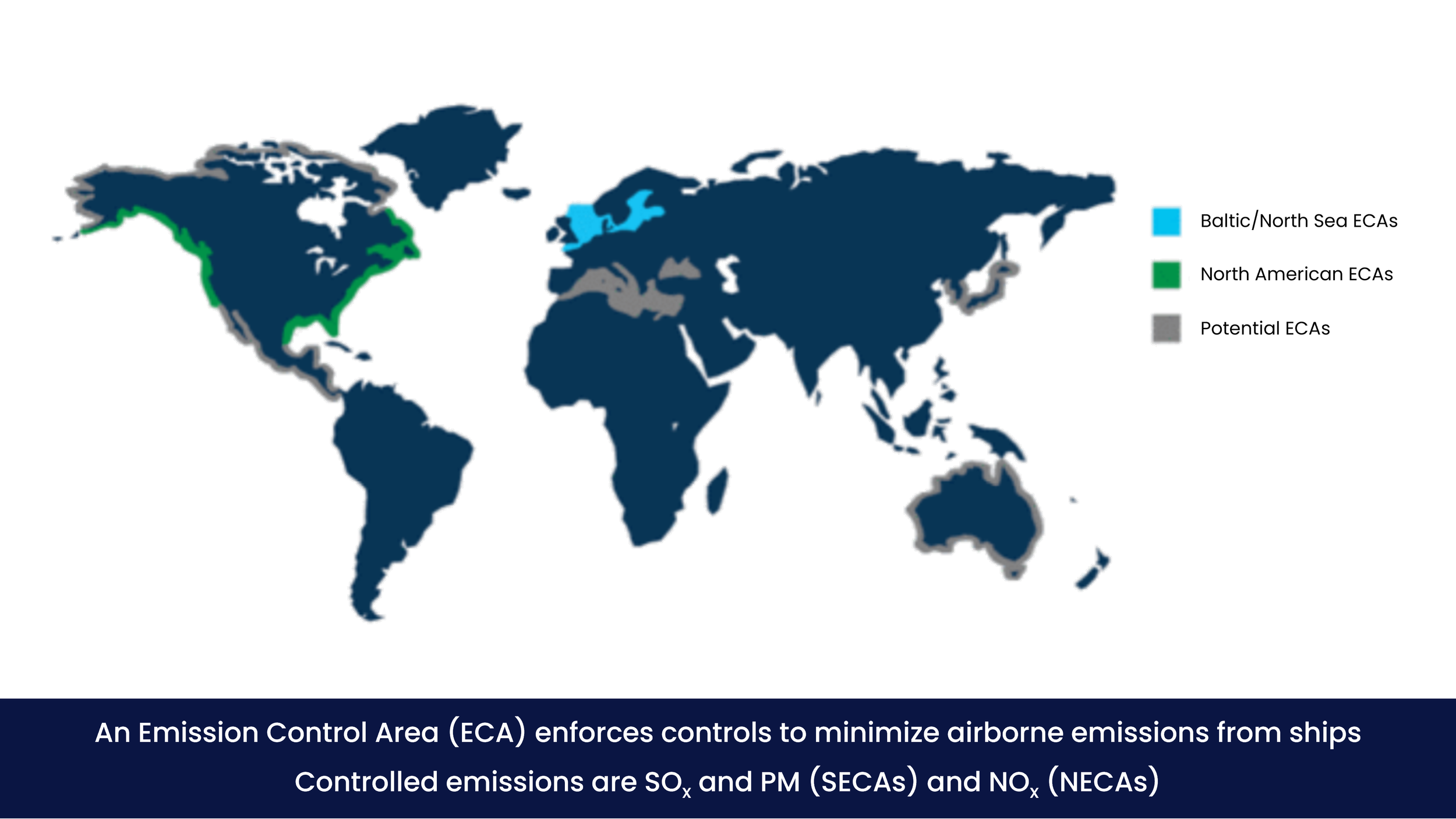

An Emission Control Area (ECA) is a sea area in which stricter controls to minimize airborne emissions from ships are established.

Initially this regulation was aimed to reduce sulphur oxides (SOX) and is extended in 2005 to include nitrogen oxides (NOX) for several areas. ECAs with restrictions on SOX only are sometimes referred to as SECAs. ECAs with restrictions on NOX are sometimes referred to as NECAs.

-

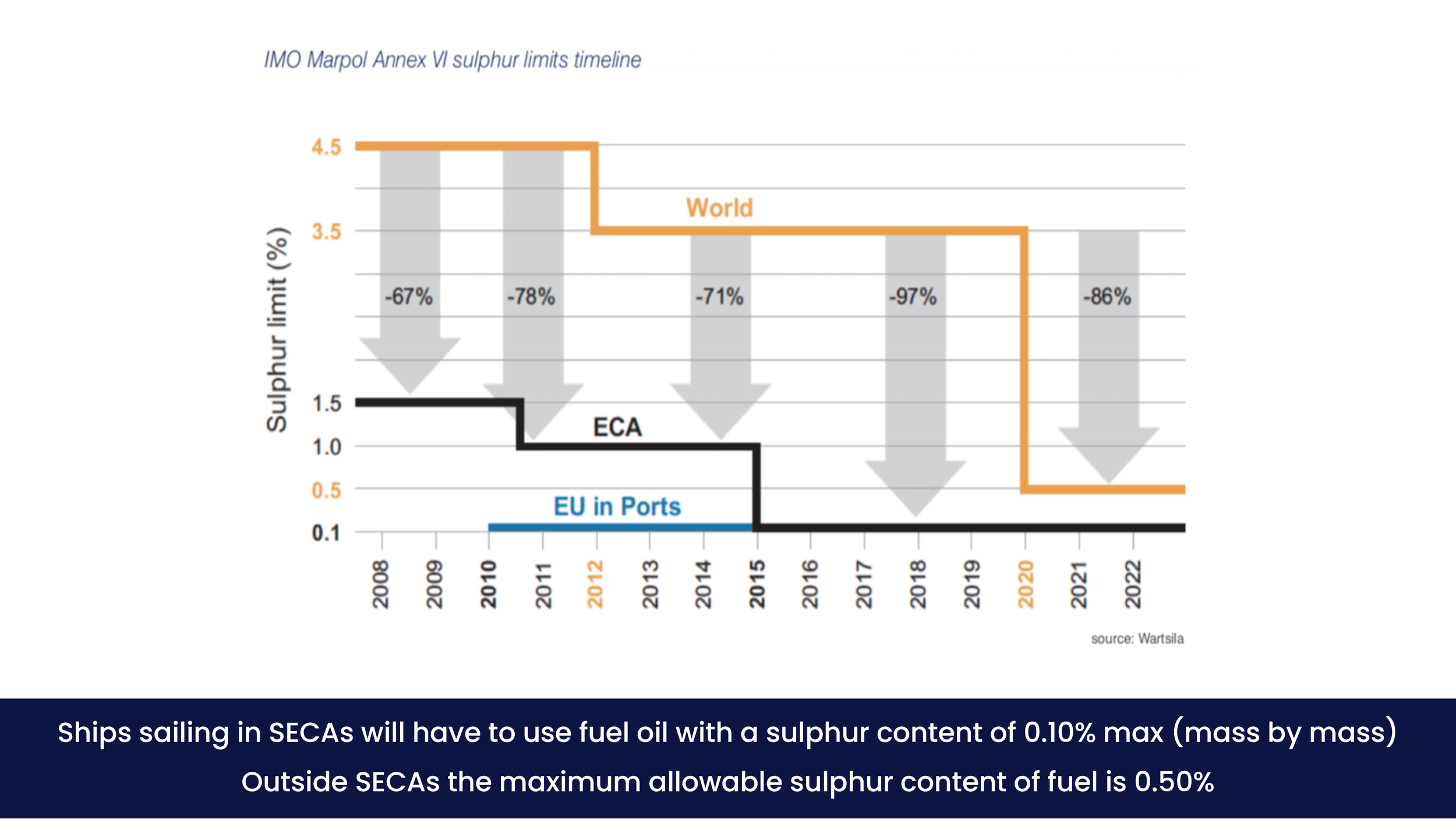

Ships sailing in emission control areas will have to use fuel oil on board with a sulphur content of no more than 0.10% (mass by mass). The interpretation of “fuel oil used on board” includes use in main and auxiliary engines and boilers.

The rules are part of the International Convention for the Prevention of Pollution form ships (MARPOL) Annex VI (Regulations for the Prevention of Air Pollution from Ships), specifically under regulation 13, which cover Nitrogen Oxides (NOx) emissions, and 14, which covers emissions of Sulphur Oxides (SOx) and particulate matter (PM) from ships.

-

The below ECAs are currently ‘active’ according to IMO.

Regulation 13 / MARPOL VI NOx control

Baltic Sea Area

North Sea Area

North American Area West

North American Area East

Hawaii Area

Unites States Caribbean Area

Regulation 14 / MARPOL Annex VI (SOx and PM)

Baltic Sea Area

North Sea Area

North American Area West

North American Area East

Hawaii Area

Unites States Caribbean Area

-

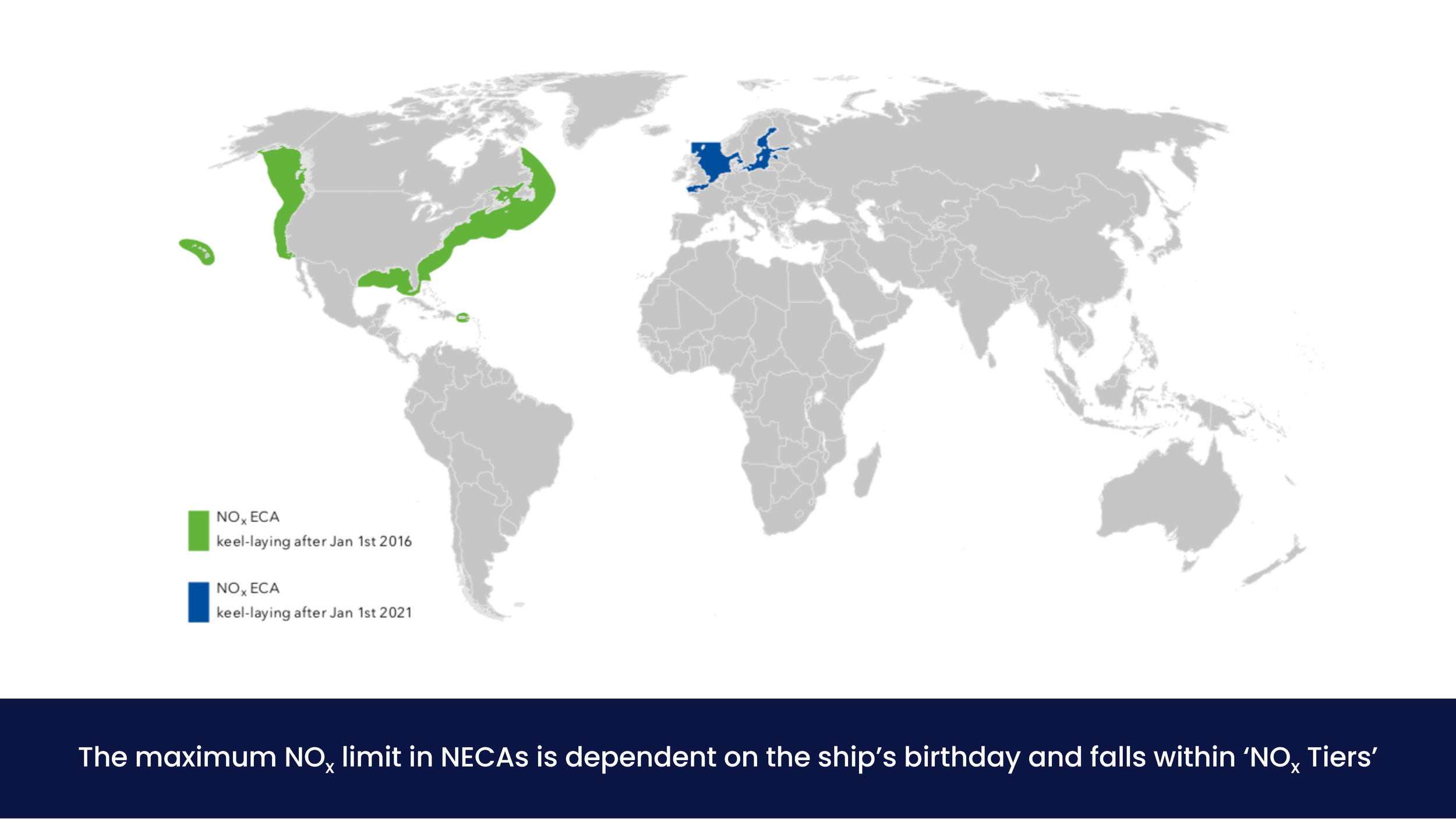

IMO Regulations under MARPOL Annex VI state that at the time of writing all ECAs are SOx constrained (SECAs) and all ECAs are NOx constrained (NECAs). However, the application of NOx Tier II in the ECAs applies when the ship is constructed on:

1 January 2016 and operating in the North American ECA and the United States Caribbean Sea ECA; or

1 January 2021 and operating in the Baltic Sea ECA or the North Sea ECA.

-

An Emission Control Area (ECA) is a general term that applies to SOx, PM and NOx emissions control. IMO NOx tiers apply to all areas and all ships constructed after a specific date. Special rules apply inside a NOx Emission Control Area (NECA).

A NECA is an area with stricter NOx emission regulations, as dictated by MARPOL Annex VI regulation 13. Within a NECA, so called Tier III NOx limits apply. Outside NECAs, the maximum applicable Tier is II. Compliance to Tier III control is also dependent on a vessel age.

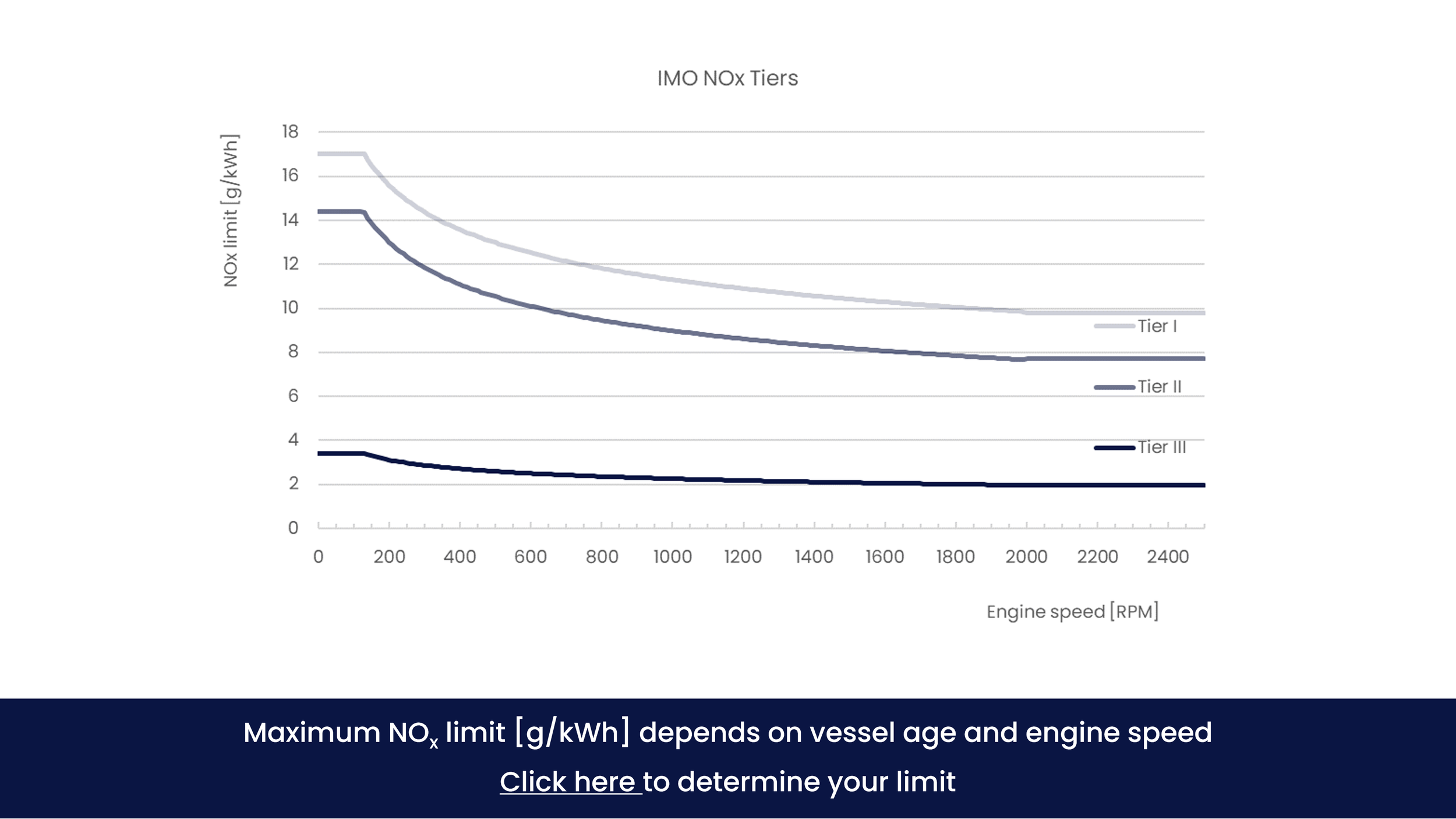

In NECAs, only engines installed on a ship constructed on or after a specific date must comply with Tier III. The regulation applies globally to any installed diesel engine above 130 kW output power and sets limits [g/kWh] based on the rpm.

A marine diesel engine that is installed on a ship constructed on or after the following dates and operating in the following NECAs must comply with the below Tier III NOx standard. Outside these areas, Tier II or I applies pending vessel age.

1 January 2016 and operating in the North American ECA and the United States Caribbean Sea ECA; or

1 January 2021 and operating in the Baltic Sea ECA or the North Sea ECA.

-

Any pre-2000 vessel has to comply with Tier I NOx limit.

2008 Annex VI Amendments (Tier II/III) adopted in October 2008 introduced not only new fuel quality requirements beginning from July 2010, Tier II and III NOx emission standards for new engines, but also Tier I NOx requirements for existing pre-2000 engines.

Furthermore it applies retroactively to new engines greater than 130 kW installed on vessels constructed on or after January 1, 2000, or which undergo a major conversion after that date. The regulation also applies to fixed and floating rigs and to drilling platforms (except for emissions associated directly with exploration and/or handling of sea-bed minerals).

-

Flag States must issue an International Air Pollution Prevention (IAPP) Certificate to the ship. This includes a section to state that the ship uses fuel oil with a sulphur content that does not exceed the applicable limit value as documented by bunker delivery notes; or uses an approved equivalent arrangement.

Ships taking on fuel oil for use on board should have a bunker delivery note, which states the sulphur content of the fuel oil supplied. Samples may be taken for verification. Port and coastal States can use port State control to verify that the ship is compliant. They could also use surveillance, for example air surveillance to assess vessel smokestack plumes, and other techniques to identify potential violations.

-

Sanctions are established by individual Parties to MARPOL, as flag and port States. There is no established fine or sanction set by IMO – it is down to the individual State Party.

-

With regards to SOx reduction, a shipowner can choose between changing fuel or installing a scrubber.

Change fuel

Ships can meet the requirements by using low sulphur fuels such as Marine Gas Oil (MGO) or Marine Diesel Oil (MDO), sometimes referred to as distillates, or even Liquified Natural Gas (LNG).

MARPOL Annex VI regulation 4.6 requires ships using separate fuel oils to carry a written procedure showing how the fuel oil change-over is to be done, allowing sufficient time for the fuel oil service system to be fully flushed of all fuel oils exceeding the applicable sulphur content prior to entry into an ECA. The volume of low sulphur fuel oils in each tank as well as the date, time, and position of the ship when any fuel-oil change-over operation is completed prior to the entry into an ECA or commenced after exit from such an area, must be recorded in such log-book as prescribed by the Administration.

Install scrubber

Alternatively one can make use of scrubbers, which remove the SOx from exhaust gasses. In this case, the equivalent arrangement must be approved by the ship’s Administration (the flag State) that is a State Party to MARPOL Annex VI.

With regards to NOx reduction, multiple options are available, including:

Selective Catalytic Reduction (SCR)

Exhaust Gas Recirculation (EGR)

LNG in lean-burn (Otto) engines or turbines

-

Exemptions are provided for securing the safety of the ship or saving life at sea, or as a result of damage to a ship or its equipment. Also, provisions for trials for ship emission reduction and control technology research provide for a time limited exemption.

-

Outside the emission control areas, the current limit for sulphur content of fuel oil is 0.50% [m/m]. Vessels are subject to NOX Tier limits pending their age, either Tier I (2010 or older) or Tier II (2011 or younger).

About ECAs

An Emission Control Area (ECA) is a sea area in which stricter controls to minimize airborne emissions from ships are established. Initially this regulation was aimed to reduce sulphur oxides (SOX) and is extended in 2005 to include nitrogen oxides (NOX) for several areas. ECAs with restrictions on SOX only are sometimes called SECAs. ECAs with restrictions on NOX are sometimes called NECAs.

-

Since 1 January 2015, the sulphur limit for fuel oil used by ships operating in emission control areas is reduced to 0.10% mass by mass [m/m]. Ships have to comply to specific NOx limits, pending their age. Most commonly this is done by means of a fuel change or the installation of a scrubber.

There are four existing SECAs: the Baltic Sea, the North Sea, plus the North American ‘East’ and ‘Western’ seas, i.e. most of US and Canadian coast and the US Caribbean (click here for the exact coordinates).

The Mediterranean will be included as SECA in 2025. Several countries, including China, South-Korea and Australia have already nominated their territorial waters to become a SECA.

-

For more on NOx Tiers, click here.

In addition to SOx, international agreements have been made for maritime shipping regarding the establishment of a NOx Emission Control Area (NECA) in the North Sea (and Baltic Sea) and US.

In these NECAs, Tier III NOx controls apply to applicable ships. Outside NECAs, Tier II controls apply. Engines with the Tier III standard may emit approximately 70% less NOX than the marine engines from 2011 (Tier II standard) and more than 80% less NOX than the marine engines from 2000 (Tier I standard).

A marine diesel engine that is installed on a ship constructed on or after the following dates and operating in the following ECAs shall comply with the Tier III NOx standard:

1 January 2016 and operating in the North American ECA and the United States Caribbean Sea ECA; or

1 January 2021 and operating in the Baltic Sea ECA or the North Sea ECA.

Compliance to Tier III control is dependent on a vessel age. In NECAs, only engines installed on a ship constructed on or after 1 January 2016 must comply with Tier III. The regulation applies globally to any installed diesel engine above 130 kW output power and sets limits [g/kWh] based on the rpm:

Tier I, ships built after 2000:

○ rpm < 130: 17 [g/kWh]

○ 130 < rpm < 1999: 12.1 [g/kWh]

○ 2000 < rpm: 9.8 [g/kWh]

Tier II, ships built after 2011;

○ rpm < 130: 14.4 [g/kWh]

○ 130 < rpm < 1999: 9.7 [g/kWh]

○ 2000 < rpm: 7.7 [g/kWh]

Tier III, (only in ECAs) for ships build after 2016:

○ rpm < 130: 3.4 [g/kWh]

○ 130 < rpm < 1999: 2.4 [g/kWh]

○ 2000 < rpm: 2.0 [g/kWh]

Compliance

Compliance to the sulphur limits require different approach and imply different cost and operational impacts as opposed to adhering to NOx Tier limits. Below options may be considered to comply with regulations for SECAs and NECAs.

-

Guidelines intended for use by Administrations, port States, shipowners, shipbuilders and fuel oil suppliers have been provided in MEPC.320(74).

Multi-fuel

The most common option for most shipowners at the moment, is to have two or more separate fuels on board. These could be low-sulphur and high-sulphur fuels (with a maximum of 0.50% sulphur content) or even marine diesel oils as opposed to heavy fuel oils. Fuel options are of course limited by the engine design and should be discussed with the chief engineer and Original Engine Manufacturer (OEM) if needed.

Change fuel

Alternatively one can switch to LNG as marine fuel as sulphur content of LNG is virtually zero. This will have a severe cost impact and is generally not recommended for refits, but a larger number of newbuilds destined for international voyage will be using LNG (roughly 30% at the time of writing). An advantage of using LNG is that compliance to NOx limits will be easier. A disadvantage is that IMO rules and regulations for low-flashpoint fuels will apply.

SOX scrubber

Alternatively an aftertreatment system can be installed to remove the sulphur from the exhaust gas. This can be done with open-loop scrubbers or closed-loop scrubbers. Open-loop systems simply remove the SOx from the exhaust gas and insert it into the seawater. Closed-loop systems will store the SOx sludge, after which it has to be handled when in port. Specific IMO regulations apply as described by the 2015 guidelines for exhaust gas cleaning, resolution MEPC.259(68).

Check out the masterclass for more information on the operational and cost impact of these measures.

-

Tier II standards are - in most cases - ensured by the engine manufacturers. Tier III standards however impose significant challenges for engine manufactures, ship operators and certifiers from a technical and operational point of view, as without specific treatment of the exhaust gases the emission limits for NOx are unlikely to be met.

Typical measures to reduce NOx emissions includes - among others - optimizing engine settings, water-injection, the use of selective catalytic reductors, or the use of electric energy storage. Below is an overview of technologies and their reduction potential to meet the Tier II and Tier III requirement by DNV. Naturally more solutions are available, such as full electric propulsion or the use of hydrogen in an electrolyser setup. These are however less practical and far from affordable in many retrofit cases and are this not shown here.

Check out the NOx Tiers page to learn more about compliance measures, click here to learn more.

Or purchase the masterclass for more detailed information.

References

IMO - MARPOL Annex VI Regulation 13 - Nitrogen Oxides (NOx)

IMO - MARPOL Annex VI Regulation 14 - Sulphur Oxides (SOx) and Particulate Matter (PM)

IMO - Emission Control Areas (ECA) designated under MARPOL Annex VI Appendix VII

IMO - NOx Regulation 13

IMO - MEPC.202(62) Amendment of 1997 protocol for stricter emission control

IMO - MEPC.320(74) Guidelines for implementation of sulphur limit

REMPEC - Workshop on Ratification and Effective Implementation of MARPOL Annex VI