Wattlab

Wattlab develops custom solar energy systems. With roots originating from the Vattenvall Solar Team, Wattlab builds upon their own expertise by bringing solar energy and technology to the shipping industry.

By applying thin and lightweight solar panels in the marine industry, Wattlab aims to contribute to a solution for the climate problem. The solar hatches’ energy can be used to power the onboard applications that are otherwise powered by a generator. On hybrid ships, the generated solar energy supports propulsion. The elimination of genset and fuel use results in less pollution and noise for the environment. As the usage of a generator is no longer allowed in some ports, it is required to connect to shore power, which is not always facilitated well. The use of solar hatches allows the captain more freedom as the vessel is not reliant on a fixed location with shore power.

You might also like

This is a case study on how to decarbonize an inland waterway ship with solar PV technology. Flexible solar PV panels from Wattlab are placed on an inland ship’s hatches in order to reduce fuel consumption while idling or moored. In some cases, the auxiliary generators can be switched off, resulting in an expected CO2 reduction of 26% - 100%.

Thailand is close to completing one the world's biggest hydro-floating solar hybrid farms on the surface of a dam, part of steps towards boosting renewable energy production after years of criticism for reliance on fossil fuels.

Equinor will explore opportunities within the realm of floating solar power. Together with Moss Maritime the company wants to start testing near the island of Frøya in the late summer of 2021. The plant will measure 6400 m2 and rise 3 meters above sea level and appears to be made of interlinked rigid structures.

Does floating solar work in high waves and storms? Yes. It most certainly does.

This blog sketches a vision on how to convert the largest crane vessel in the world - Sleipnir - owned by Heerema Marine Contractors, to a zero-emission vessel. Several promising carbon reduction measures are combined which are technically viable and based on matured technology including electrification and BES, solar panels, synthetic fuels, CCS and possibly hydrogen combustion.

Solar PV is integrated with the local water treatment system on Tengeh Reservoir in Singapore, offsetting 6% of its annual energy needs for 25 years.

Kind of what you expect. A full-scale behavioral analysis of a 4 [MW] floating solar system by Foresys. Made in Orcaflex.

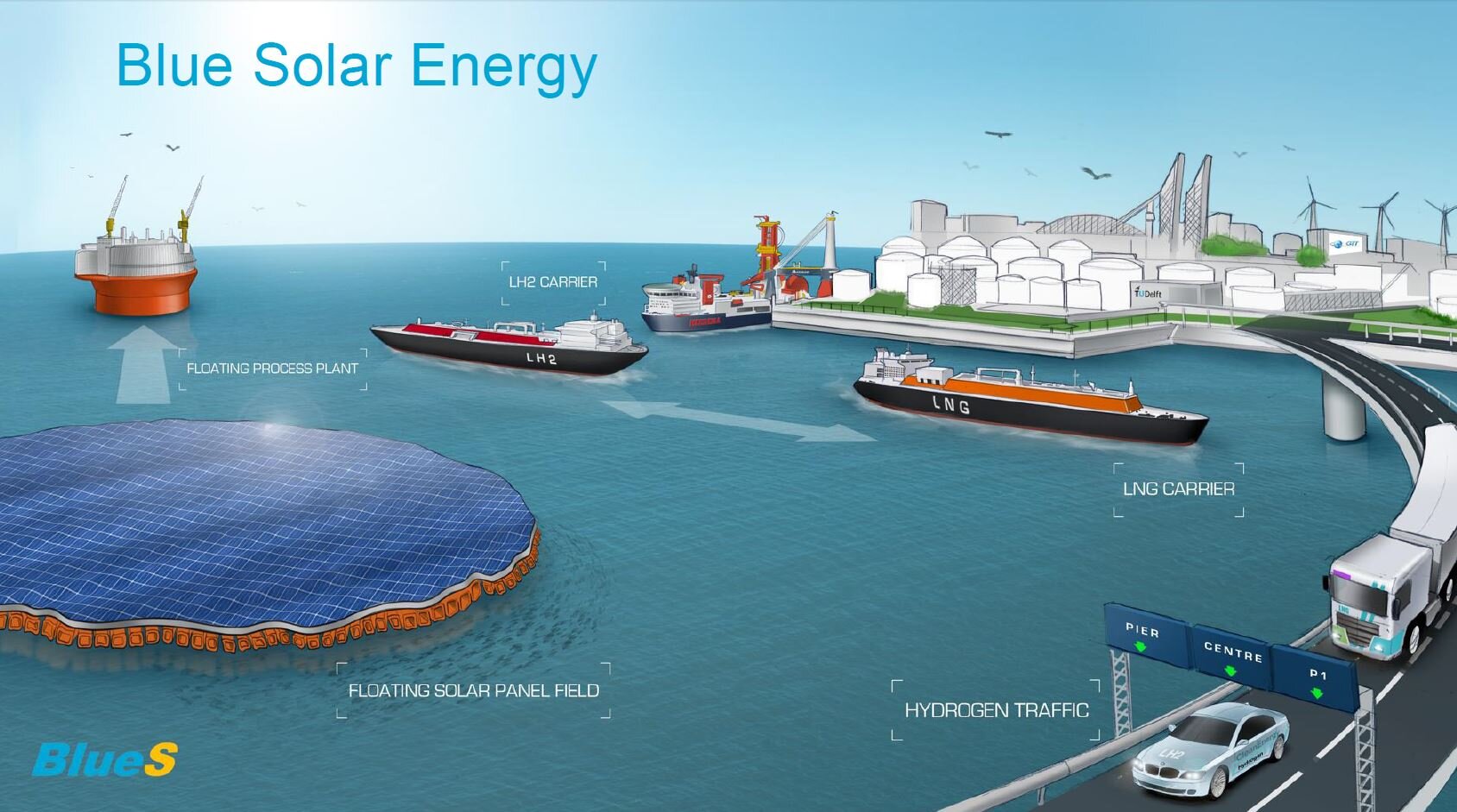

People think we need energy. Truth is, we do not. We need heating, lighting and transportation. At the right place, on the right time. Generating energy is not the issue, the trick is how to transform it into useful energy and store it. So how can we combine the cheapest form of energy generation with energy storage? What is the best place to generate gigantic, ridiculous amounts of energy? As in tenths of gigawatts, the size of small countries? In the desert with solar energy? Think again.

This case study explores a 100 kWp solar PV system installed on the hatch covers of a handymax bulk carrier. Operating primarily in Northern Europe, the system offsets auxiliary engine load during idle periods, leading to estimated savings of ~$350,000 between 2025 and 2035. With a CAPEX of $100,000, the payback period is around three years. Most savings come from fuel reduction, with additional benefits from EU ETS and FuelEU compliance. The business case is most sensitive to engine efficiency (SFC) and fuel price.